|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

Fisher

Body Division of General Motors in World War Two

Detroit, MI

1908-1986

Rest in Peace

Gone but not Forgotten!!!

"Body by Fisher" became "Body Armament by Fisher" during the

Second World War

This page updated

7-5-2021.

Nothing more can attest to the contribution

of Fisher Body to the effort to win World War Two than this Fisher Body built M4A3

Sherman Tank combat veteran that is on display in downtown

Bastogne, Belgium, and which was knocked out of combat during the one of the

most famous battles of World War Two, the Battle of the

Bulge, in December of 1944. It sits at the intersection of several

roads in Bastogne that made the town an important military objective

during the battle.

Author's photo added 4-6-2015.

Fisher Body was the

premier division of General Motors during the Second World War from a size, production,

and documentation standpoint. No other GM Division or US Auto

Company documented what it did as well as Fisher Body with respect to

numbers of weapons produced and in which plant they were produced.

But one would only expert this of what at one time was GM's premier

division.

However, unless one worked

in the auto industry previous to the 21st century there is probably no

name recognition with the term Fisher Body. But everyone who owned a GM

car or light duty truck built previous to 1986, or even a year or two

after, had the Fisher Body insignia on the door sills of their cars. The

driver and passenger

would see it every time got they in and out of the car.

Fisher Body assembled the passenger compartment which was then trucked

to the final assembly plant where it as dropped on to the chassis of an

Oldsmobile or other GM car. While most people had or have name

recognition of the current and former GM care lines, most will not

recognize the name Fisher Body, in spite of seeing it every time they

opened the car door. Fisher Body was a big GM division and may

have been as large as Chevrolet, if not larger.

Growing up in Lansing, MI,

the home of the former Olds Division, I would have problems telling my

friends that my dad worked at Fisher Body. If your dad worked at

Oldsmobile, they would know what and where that was. But Fisher

Body, even when it was the second largest private employer in Lansing at

5,000, would be a mystery to most persons.

When one opened the door of their pre 1986

GM car or light duty truck, they would see the Fisher Body Emblem on the

door sill. With the exception of the instrument panel (dashboard)

and steering wheel, everything else pictured here was assembled at the

Fisher Body Plant. Author's Photo.

Body by Fisher. It used to be these were oval shaped.

Author's Photo.

The most coveted award

sought by plants making war material during WWII was the prestigious

Army-Navy "E" Award. Only 5% of the eligible plants

received the award during WWII. This was truly and

extraordinary feat by the Fisher Body organization and attests to the

fact it was the premier Division of General Motors during the war!

|

Fisher Body

Plants that won the Army-Navy "E" Award during WWII |

|

Fisher Body Plant |

Number of times "E" Award won |

|

Fisher Body Division, Aircraft Unit, Plant #21, Detroit, MI |

4 |

|

Fisher Body Division, Central Development and Experimental Unit,

Plant #21, Detroit, MI |

2 |

|

Fisher Body Cleveland Division, Plant 1, Cleveland, OH |

1 |

|

Fisher Body Cleveland Aircraft Division, Plant 2, Cleveland, OH |

1 |

|

Fisher Body Division, Fleetwood Plant, Detroit, MI |

4 |

|

Fisher Body Division, Stamping Unit #37, Detroit, MI |

2 |

|

Fisher Body Division, Ternstedt Manufacturing Division, Division

#9, Detroit, MI |

2 |

|

Fisher Body Division, Ternstedt Manufacturing Division, Main

Plant, Division #3, and Plant 15, Detroit, MI |

1 |

|

Fisher Body Division, Die and Machine Unit, Detroit, MI |

7 |

|

Fisher Body Division, Flint #1, MI |

5 |

|

Fisher Body Division, Grand Blanc Tank Plant, Grand Blanc, MI |

5 |

|

Fisher Body Division, Grand Rapids Stamping Plant, MI |

1 |

|

Fisher Body Division, Lansing , MI |

1 |

|

Fisher Body Division, Memphis Aircraft Plant, Memphis, TN |

4 |

|

Fisher Body Division, Pontiac, MI |

1 |

Fisher Body World War Two / WWII Production

Numbers

(Armament by Fisher) :

Aviation -

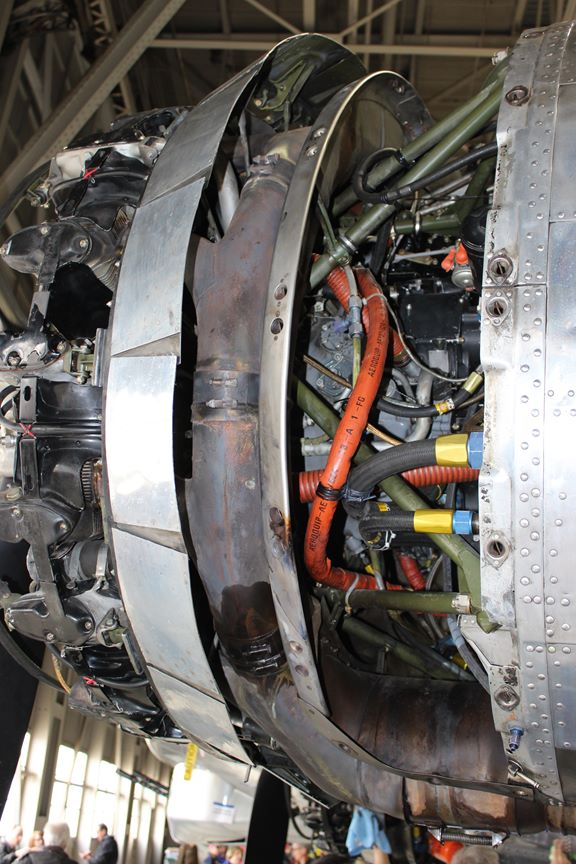

B-17 - (68,612) B-17 exhaust

collector systems, (46,748) B-17 fixed engine cowlings and (40,228) B-17

removable engine cowlings

Fisher Body Division of General Motors built

46,748 B-17 fixed engine cowlings and 40,228 B-17 movable

engine cowlings at several of its plants. Author's Photo.

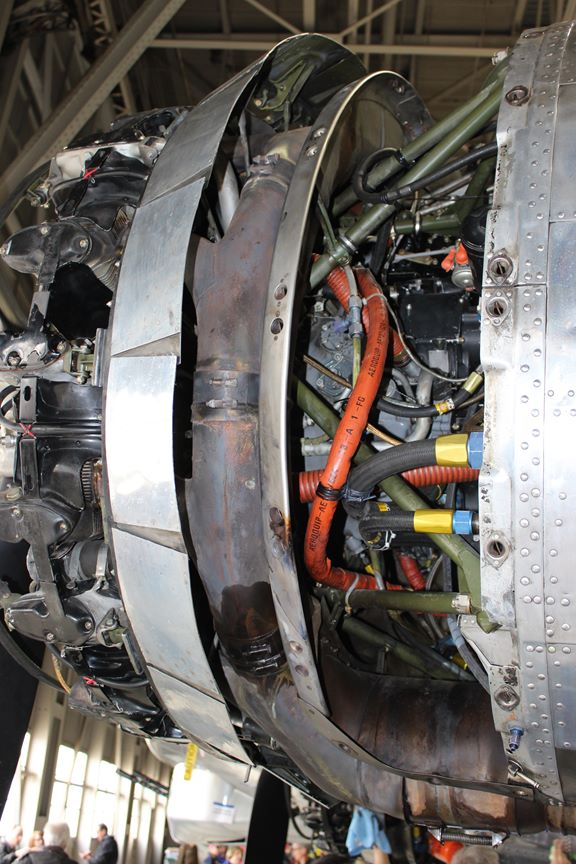

Fisher Body Division of General Motors built

68,612 B-17 exhaust collector systems like this one on the B-17 "Yankee

Lady." Also show is the movable engine cowling. Author's

Photo.

B-25 - (5,214) B-25 Bomber Assemblies

which included the fuselages, wings, tail assemblies, exhaust collectors

along with forgings, castings and machined parts, all of which went to

the North American Plant in Fairfax, KS. At the beginning of

the war, Fisher Body supplied 55% of the content in these B-25s.

Production started in

early 1941 and continued through June of 1945. Ten Fisher Body

Plants were involved. See pages 4-7 of the the

Fisher Body - Aircraft Page for more specific information and

photos on Fisher Body and the B-25 project during WWII.

This B-25J Mitchell Bomber was one of 4,318

J models built at the North American B-15 plant in Fairfax, KS during

the war. North American also built 2,290 D model at Fairfax. In Detroit

the B-25 assemblies were built at its Stamping, Detroit Aircraft Unit, Central Development and

Experimental Unit, Fleetwood, and Ternstedt plants. Grand

Rapids, MI, Memphis, TN, Cleveland, OH and Pontiac, MI Fisher Body

Plants also made B-25 parts. Author's Photo.

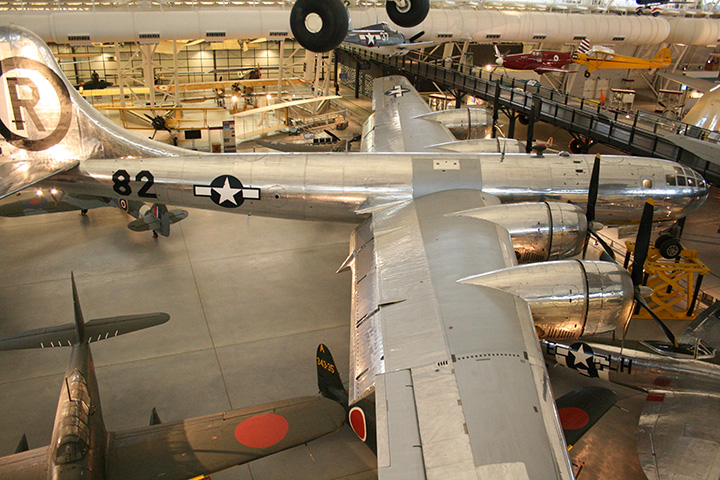

B-29 -

(13,772) B-29 Engine Nacelles. Fisher

Body also built horizontal

stabilizers, vertical stabilizers, rudders, elevators, outboard wing

sections, flaps, exhaust collectors, engine cowlings, tail gun turrets

and rudder pedals along with many miscellaneous parts.

In June of 1942 the USAAF contracted with

Fisher Body to build 200 B-29s in a new plant built in Cleveland just

for that purpose. A year later it was decided to instead have the

Martin plant in Omaha, NB that had stopped production on the B-26 build

those B-29s.

Fisher Body then concentrated on building the above listed components,

many of them going to Martin Omaha. The B-29 Silverplate atomic

bombers, including the "Enola Gay" and "Bockscar",

were built in Omaha. Fisher Body provided many of the components as listed above

for these historic bombers.

Some historians and websites say the Fisher

Body built entire B-29s. This is untrue. It was scheduled to do

so, but the situation changed and the work went to Martin Omaha.

Page 8 of the attached official end of war Fisher Body document

Fisher Body - Aircraft makes that very clear.

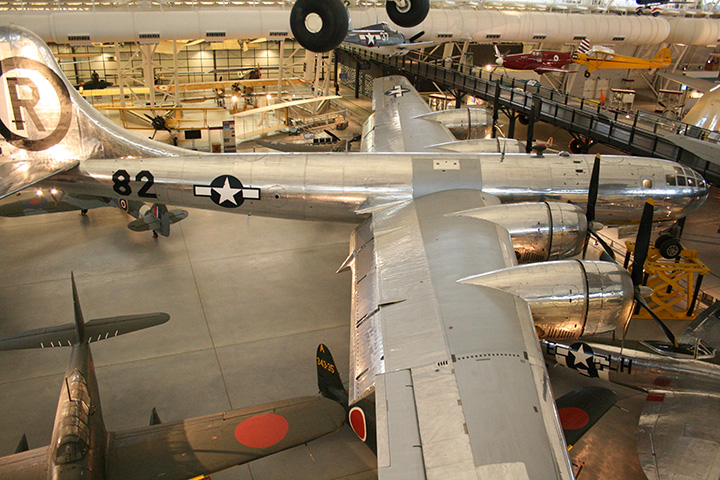

The B-29 "Enola Gay" as seen at the

Udvar-Hazy Center in Virginia. What connection does it have with

Fisher Body? Originally when the B-29 program began Fisher Body

received a contract to build at least 200 B-29s in its Cleveland plant,

along with parts to supply other B-29 final assembly plants in the

nation. Later in the war it was decided by the military to move

the final assembly of B-29s from Fisher Body Cleveland to the former

Martin B-26 plant in Omaha, NB which was no longer producing the B-26.

Fisher Body then became one of the prime suppliers of B-29 airframe

components to the Martin B-29 Plant. The "Enola Gay", seen here,

and "Bockscar", located at the Air Force Museum in Dayton, OH were the

two B-29s to drop the atomic bombs on Japan to end the Second World War.

Both were built in Omaha and had Fisher Body components. Author's

Photo.

Fisher Body built 13,772 B-29 engine

nacelles at its Cleveland #2 plant in the Second World War. 3,663 B-29s were

built with four nacelles each meaning Fisher Body built 90% of them.

It also built horizontal stabilizers, vertical stabilizers, rudders,

elevators, outboard wing sections, flaps, exhaust collectors, engine

cowlings, tail gun turrets and rudder pedals along with many

miscellaneous parts. Author's Photo.

Aircraft

- (13) P-75 Eagles. These were built at the Cleveland Plant 2.

The only surviving Fisher Body XP-75 as seen

at the National Museum of the United States Air Force. Author's

Photo added 5-11-2015.

Other Aircraft Parts -

(20,000,000) Dzus Fastener

Blanks were stamped out by Ternstedt Division. These fasteners

when complete were used as quick release fasteners on on engine cowlings

and panels. Every aircraft had them.

(85,600) 150 Gallon Drop Tanks for the US Navy and (53,600) mounting

kits. This order probably did not get filled as shipping was to

begin after the war ended. No doubt the Navy was anticipating the

need for the drop tanks as carrier aircraft operated off the coast of

Japan during the planned invasion.

P-80 intakes and wingtips. Another order

taken on in 1945 that probably did not get filled. Some sources

have misinterpreted this information and claim that Fisher Body built

the actual aircraft in Plant 21 in downtown Detroit. The contract

was for tooling and parts, not entire aircraft.

(1,500) FG-4 Engine Cowlings. The FG-4

was to be the Goodyear built version of the Vought F4U-4 Corsair which

never went into production.

Aircraft Instruments - (168,400) Gyro Horizons,

(124,700) Directional Gyros, (46,615) Compass Transmitters, (76,291)

Compass Indicators. For the Bendix Air Position Indicator

Ternstedt Division produced (4,724) analog computers, (4,716) pumps

and (9,425) right angle drives.

Tanks, Tank Destroyers and Prime Movers:

(11,358) M4 Series Tanks, (1,799) T28E3, T26E4, M26 Tanks, (5,368) M10

Tank Destroyers, (487) M36 Tank Destroyers, (40) M39 Prime Movers.

For the complete story of Fisher Body tank

production, please view the Grand

Blanc Tank Arsenal page.

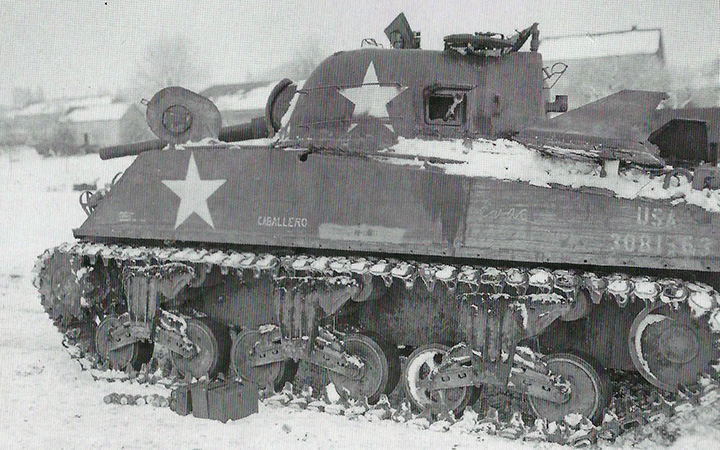

The Fisher Body built M4A3 on display in downtown Bastogne. Registration Number 3081532 was one

of 339 M4A3 Sherman tanks built in the Fisher Body Tank Arsenal in Grand

Blanc, MI in March of 1944. Author's photo added 4-6-2015.

The M4A3 Sherman tank was powered by a Ford V-8 engine and was armed

with a 75mm cannon. It was one of 1,711 M4A3s that were built by Fisher

Body between February and September of 1944. Author's photo added

4-6-2015.

This Fisher Body-built M4A3E2 is the only

tank at the newly opened National Museum of the United States Army at

Fort Belvoir, VA. This tank was built at the Fisher Body Grand

Blank tank plant in July 1944. On December 26, 1944 it was the

first tank to arrive with Patton's Third Army at Bastogne, Belgium.

Fisher Body-built tanks were at the forefront of the fighting at the

Battle of the Bulge. Author's photo added 7-5-2021.

"Cobra King" is the most famous Sherman tank

of World War Two. It was one of 254 up-armored assault tanks

built for the U.S. Army in the summer of 1944. Author's photo

added 7-5-2021.

Photo added 7-5-2021.

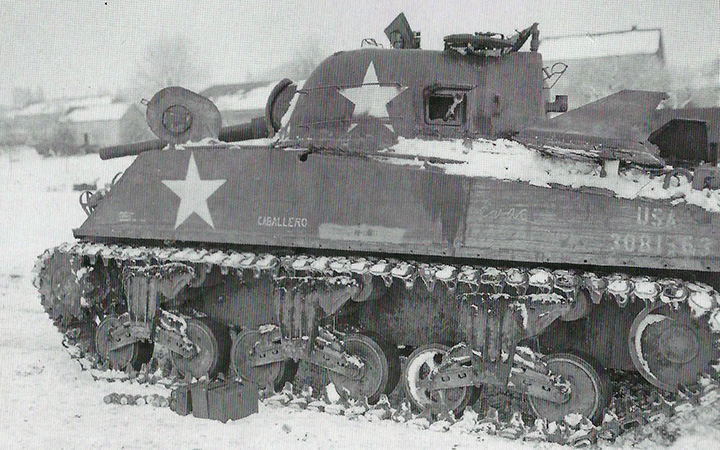

This period photo shows a Fisher Body built M4A3 tank that was also hit

by enemy fire in the Bastogne area. 3081563 was another of the 339

M4A3 tanks built in March of 1944 at the Fisher Tank Arsenal in Grand

Blanc, MI. Between February of 1944 and March of 1945 Fisher Body

built 3,071 M4A3 Sherman tanks. Photo courtesy of the Patton

Museum.

The 2014 movie Fury with Brad Pitt featured a Fisher Body built M4A2E8

Sherman Tank as the other co-star.

Fisher Body also built 5,368 M10 Tank

Destroyers like this at its Grand Blanc, MI tank plant. This one

was totally restored by the Virginia Military Vehicle Museum in 2016 and

was photographed at its annual open house. . Author's Photo added

10-24-2016.

This is an M26 Pershing tank that is on

display at Fort Jackson, SC in front of the US Army's Basic Combat

Training Museum. Fisher Body built 1,799 Pershings between

November 1944 and June 1945 at Grand Blanc, MI. The M26 was designed with a

90mm main gun to be able to be better able to defend itself against the

newer German tanks. The first twenty Pershings sent to Europe were

all Fisher Body built, and saw the majority of the action of the 300

that eventually arrived in the theatre.

Author's photo added 9-22-2015.

Tank and Tank Destroyer Components -

(2,245) M18 turrets, (1,511) M18 hulls, conversion of (600) older M18s

into M39 prime movers and the new construction of (40) new M39s.

(1,798) M8 turrets and (4,962) M5 turrets. (600) anti-aircraft

turrets for the Staghound armored car. (3,554) M24 hulls.

(100) M8 tank turrets modified for use in LVT's by the Navy.

a a

Fisher Body supplied (2,245) turrets and

(1,511) hulls for the (2,507) Buick assembled M18 Hellcat tank

destroyer. Fisher Body also removed the turrets from (600) older

M18s to make them into M39 primer movers. It also made forty brand

new M39s. Author's Photo added 5-12-2015.

For the (3,592) M24 Chaffee tanks M24

Cadillac assembled, Fisher Body produced (3,554) of the hulls.

Author's Photo added 5-12-2015.

Cadillac produced (1,824) M5 and (4,726) M5A1 Stuart tanks and Fisher

Body (4,962) M5 and M5A1 turrets. Author's Photo added 5-12-2015.

Armament -

(2,359) 90mm AA guns, (550) 120mm (4.7inch)

M1 AA Guns (550 was the total amount of these weapons produced during

the war.), (6,342) Breech Housings for 5in Naval guns, (480) 5 inch gun

mounts, (9,459) Breech Housings for 3 inch Naval Guns, (888) cradles and

arcs and (1,053) yokes for 155mm "Long Tom" artillery pieces, (1,500,000) Parts

for 20mm Cannons for Oldsmobile (551,772) 155mm shells,

(2,000,000) incendiary bomb noses and (200,000) 4.5 inch rocket fins.

Photographed at the Indiana Military Museum

in Vincennes, IN, this three inch Naval gun as one of 9,459 breech

housings produced by the weapon by Fisher Body between February 1942 and

September 1944. Author's photo added 5-6-2015.

Here is a close-up of the 584 lb breech

housing with the Fisher Body name stamped on to the side. This is

serial number 2,722 of 9,459 produced by Detroit Die and Machine

Unit. Author's photo added 5-6-2015.

This

90mm anti-aircraft gun is located at the National Electronics Museum in

the Baltimore, MD area. Fisher Body Pontia produced 2,359 90mm weapons like

this between June of 1944 and May of 1943. Author's photo added

10-24-2016.

Author's photo added 10-24-2016.

Other - (9,353)

crankcases for marine Diesel engines,

(140) planers, (250) vertical boring machines, (48) horizontal mills,

and (25) drilling and tapping machines; (50,000) cutting tools.

Fisher Body built diesel crankcases were

used in the Cannon Class Destroyer Escorts. The USS Slater located

in Albany, NY is the only Cannon Class DE still in existence.

Photo added 10-24-2016 and courtesy of Bill Maloney.

Note that the Body has been X'd out and

Armament has replaced it for the duration of WWII. B-29s

originally staged out of China for attacks on Japan so hence the Chinese

boy pictured here.

Five inch gun parts were made in Lansing by

Fisher Body.

Next in series:

Fisher Body

Craftsmanship goes to War

|

a

a